Energy is important aspect for AKR's operational activities. Climate change, which is currently being discussed globally, has also placed energy management as part of the Company’s main focus and concern. Therefore, AKR has a commitment and policy to try to use energy efficiently. AKR pays close attention to energy use and has made several energy conservation efforts in its production process.

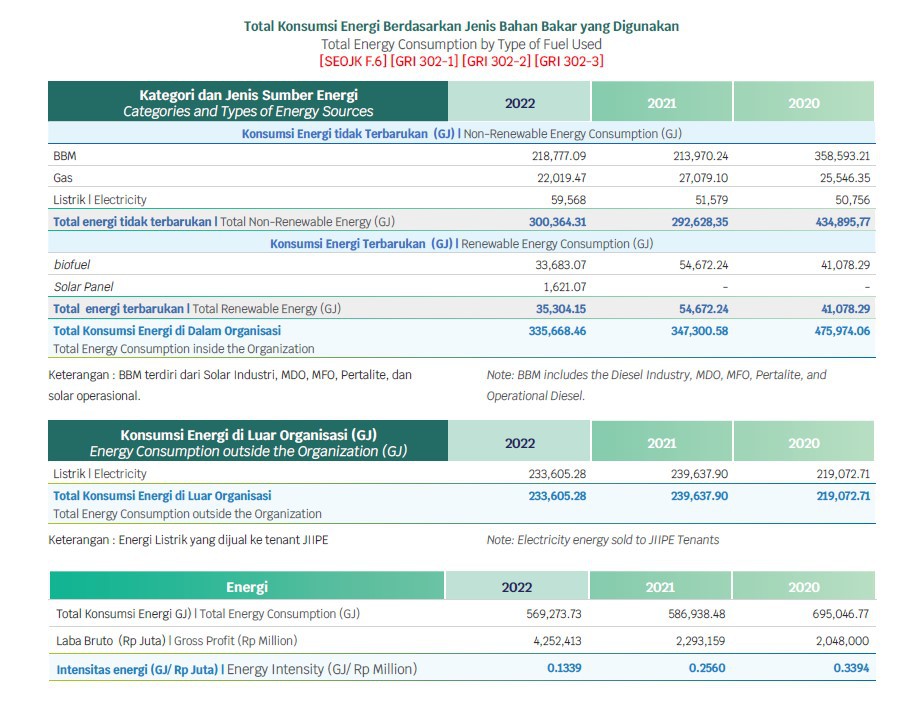

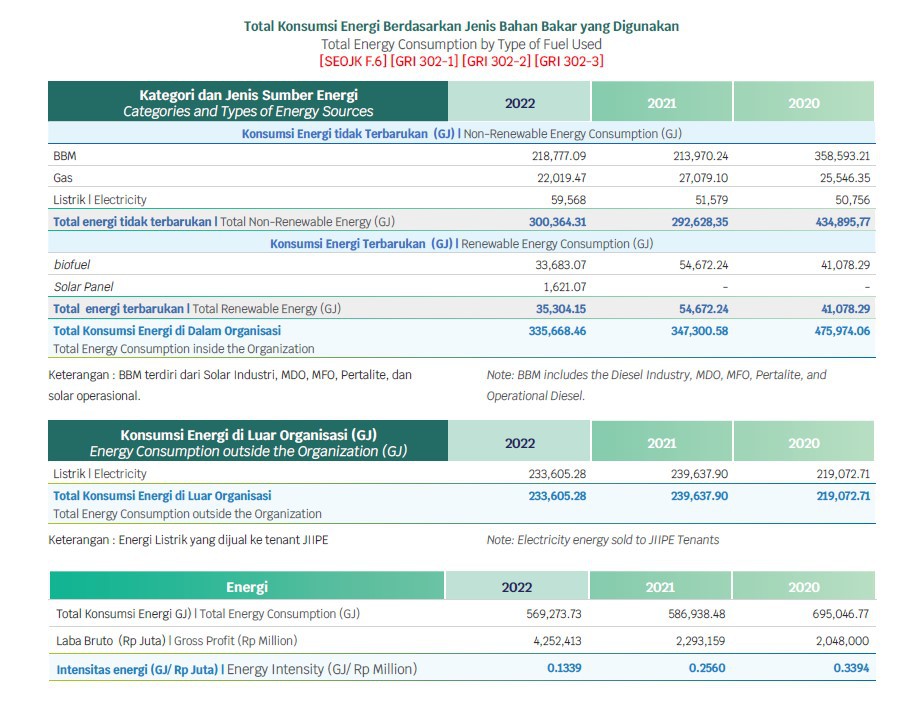

In 2022, AKR’s total energy use was recorded at 569,273.73 Gigajoules (GJ). This figure decreased compared to the previous year due to various energy efficiency efforts carried out in all AKR subsidiaries. The reduction in internal energy consumption was successfully recorded by ATI, BKMS, BMS, and DPR.

The decrease in energy consumption at ATI was driven by the implementation of Control Tower technology, hence even though transportation activities increased compared to the previous period, the overall use of fuel decreased. This was due to the ground transportation fleet’s (truck) travel routes being very well optimized. Thanks to this approach, ATI managed to record a reduction in fuel consumption from 159,719.27 GJ to 94,138.63 GJ, thereby reducing internal energy consumption by 41%.

The Company has made various efforts to reduce energy consumption, such as through the use of LED lights, solar cells, use of inverters for large capacity production motors, and so on. Until now, the use of LED lights has been implemented at BP-AKR stations, office buildings and terminals. Meanwhile, the installation of solar sensors is applied to the lights at the JTT site. The initiative to use inverters on motors with large capacity was carried out at ARUKI.

The energy intensity trend shows over the past threes years a decrease in energy use in 2022 of 3% compared to 2021. This indicates an increase in operational productivity offset by energy savings in the Company’s operational activities in line with AKR’s sustainability commitment. The decrease in energy usage was mainly due to the use of biodiesel by the AKR truck fleet. Through the IT monitoring innovation, the Company can increase the Trucks’ utilization by keep complying the standard driving parameters in the system.

The Company’s energy consumption calculation methodology we use is to collect data on petroleum purchases, electricity bills and electricity metering used by AKR and its subsidiaries. The conversion factor used to calculate energy units refers to the standards of the IPCC Guidelines for National Greenhouse Gas Inventories (2006), the World Resources Institute and the World Business Council for Sustainable Development.

Energy consumption can also occur outside the Company through the upstream and downstream operational activities. Energy consumption outside the Company is from electricity used by JIIPE-BKMS tenants. In an effort to reduce energy consumption, JIIPE-BKMS has implemented a program to reduce the volume of sludge fuel for power plants using a filtering method. The will reduce the cost of sending and managing hazardous and toxic (B3) waste to licensed third parties.

Meanwhile, energy consumption can also occur outside the Company, namely throughout upstream and downstream activities related to operations. Energy consumption outside the Company also comes from electricity used by tenants from JIIPE-BKMS. In an effort to reduce energy consumption, JIIPE-BKMS implemented a program to reduce the volume of power plant fuel sludge by filtering methods. The aim is to reduce the cost of shipping and managing B3 waste to licensed third parties from authorized agencies.

The Company continues to expand access to affordable, reliable and sustainable renewable energy. One of them is by using gas power plants as the main energy source and developing the use of solar panels in KEK Gresik JIIPE.